Key Takeaways

- Prioritize product quality by selecting manufacturers that offer heat-treated, drop-forged carbon steel connectors meeting European or U.S. standards for enhanced durability and safety.

- Evaluate pricing carefully; choose manufacturers that balance competitive pricing with high-quality materials to ensure long-term value without compromising performance.

- Research customer reviews and testimonials to gauge a manufacturer’s reputation, focusing on their reliability, product performance, and after-sales support.

- Look for unique features such as custom designs and advanced surface finishes that enhance both functionality and aesthetic appeal, catering to specific project needs.

- Consider industry-specific expertise when selecting a manufacturer, as those familiar with your sector can provide tailored solutions that meet unique operational requirements.

- Utilize flexible payment terms offered by manufacturers to manage your budget effectively, ensuring financial stability while acquiring quality products.

- Make informed decisions by comparing key metrics like product quality, pricing, reputation, and unique features across different manufacturers to find the best fit for your projects.

Criteria for Evaluating Carbon Steel Connector Manufacturers

Product Quality and Standards

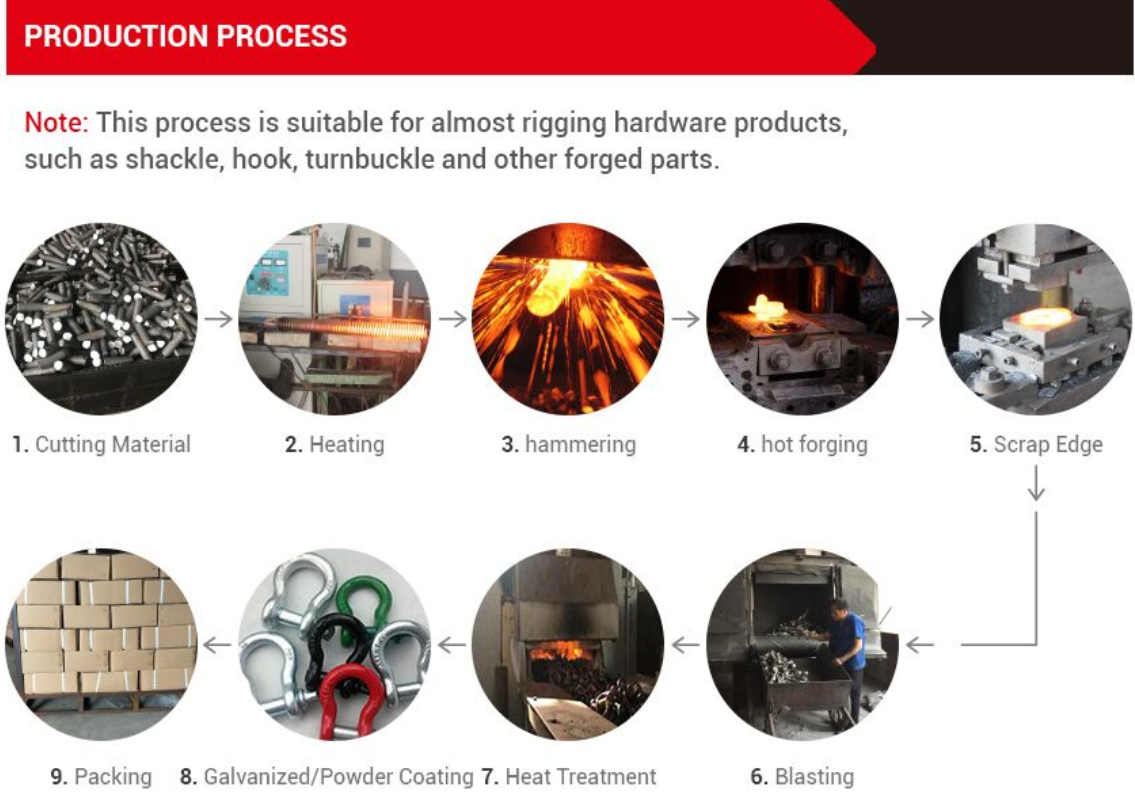

I always prioritize product quality when evaluating manufacturers. High-quality carbon steel connectors ensure durability and safety in demanding applications. Manufacturers offering heat-treated, drop-forged products stand out. These processes enhance the strength and reliability of the connectors. I also look for compliance with recognized standards like European or U.S. types. This guarantees consistency and compatibility across various industries. Additionally, I value manufacturers that provide diverse sizes and custom designs. This flexibility allows businesses to meet specific project requirements. Surface finishes, such as hot-dipped galvanized or color-painted options, also play a crucial role. These finishes protect the connectors from corrosion and extend their lifespan.

Pricing and Cost-Effectiveness

Cost-effectiveness is another critical factor. I believe a good manufacturer balances competitive pricing with uncompromised quality. While low prices may seem attractive, they often come at the expense of durability or performance. Reliable manufacturers offer reasonable pricing without cutting corners on materials or production processes. For instance, those providing carbon steel connectors with ISO-certified management systems and internal quality control teams deliver excellent value. I also appreciate manufacturers that offer flexible payment terms, such as partial deposits and balance payments upon delivery. This approach supports businesses in managing their budgets effectively.

Reputation and Customer Reviews

A manufacturer’s reputation reflects its reliability and commitment to quality. I always research customer reviews and testimonials to gauge satisfaction levels. Positive feedback often highlights consistent product performance and excellent customer service. Manufacturers with over a decade of exporting experience tend to have a proven track record. Their ability to handle international markets demonstrates professionalism and adaptability. I also consider after-sales support as a key indicator of a manufacturer’s dedication to its clients. Companies offering quick shipments and responsive customer service build trust and long-term relationships.

Unique Features and Offerings

I always look for manufacturers that bring unique features to the table. These features often set them apart in a competitive market. Manufacturers offering heat-treated, drop-forged carbon steel connectors demonstrate a commitment to durability and strength. This process enhances the structural integrity of the connectors, making them suitable for demanding applications.

I also value flexibility in product design. Manufacturers providing various sizes or custom designs cater to specific project needs. This adaptability ensures compatibility with diverse industrial requirements. Surface finishes play a significant role as well. Options like hot-dipped galvanized, electro-galvanized, self-colored, or color-painted finishes protect connectors from corrosion. These finishes also improve the aesthetic appeal of the products.

Some manufacturers go beyond standard offerings by integrating advanced technologies. For example, internal quality control systems and ISO-certified management processes ensure consistent product quality. I appreciate companies that prioritize innovation while maintaining compliance with European or U.S. standards. This combination of quality and creativity adds significant value to their products.

Industry-Specific Applications

Carbon steel connectors serve a wide range of industries. I have seen their versatility firsthand in sectors like construction, heavy industry, and marine applications. These connectors excel in environments requiring high strength and reliability. For instance, in the mining and port industries, their durability ensures safety under extreme conditions.

In the energy sector, carbon steel connectors support critical infrastructure. Their ability to withstand high pressure and temperature makes them ideal for pipelines and power plants. I also notice their frequent use in bridge construction and pole line hardware. These applications demand connectors that meet stringent safety and performance standards.

Manufacturers catering to specific industries often provide tailored solutions. For example, some focus on rigging hardware for daily use, while others specialize in connectors for marine environments. This industry-specific expertise ensures that the products meet unique operational requirements. I always recommend choosing a manufacturer with experience in your industry to guarantee optimal performance.

Top 10 Carbon Steel Connector Manufacturers

Manufacturer 1: Amphenol

Overview of Products and Services

Amphenol offers a wide range of carbon steel connectors designed for industrial and commercial applications. Their product line includes heat-treated, drop-forged connectors that meet European and U.S. standards. I have noticed their focus on providing various sizes and custom designs to cater to specific project needs. Their surface finishes, such as hot-dipped galvanized and electro-galvanized options, ensure durability and resistance to corrosion.

Strengths and Unique Features

Amphenol stands out for its commitment to innovation and quality. Their connectors undergo rigorous testing to meet industry standards. I appreciate their ability to deliver products with advanced features, such as enhanced structural integrity and compatibility with diverse applications. Their reputation for reliability makes them a preferred choice for demanding environments.

Pricing and Market Position

Amphenol positions itself as a premium manufacturer. While their pricing reflects the high quality of their products, I find their offerings cost-effective in the long run due to their durability and performance. Their competitive market position highlights their ability to balance quality with value.

Customer Feedback and Reputation

Customer reviews often praise Amphenol for their consistent product quality and excellent customer service. Many clients highlight their quick response times and professional support. Their long-standing presence in the market reinforces their reputation as a trusted manufacturer.

Manufacturer 2: China Base Ningbo Foreign Trade Co., Ltd.

Overview of Products and Services

China-Base specializes in innovative carbon steel connectors. Their product range includes heat-treated, drop-forged connectors that comply with European and U.S. standards. I have seen their dedication to offering various sizes and custom designs, ensuring compatibility with different industrial requirements. Their surface finishes, such as self-colored and color-painted options, enhance both functionality and aesthetics.

Strengths and Unique Features

China-Base excels in integrating advanced technologies into their products. Their connectors are designed for high performance, making them suitable for critical applications. I value their focus on durability and adaptability, which sets them apart in the competitive market.

Pricing and Market Position

We have a team with more than 30 years of foreign trade and management experience and professional level in R&D, purchasing, logistics management, and product development departments. Our mission is to provide global business customers with China’s best products and supply chain. We collaborate with excellent Chinese factories with strong production capacity and high product quality control (currently working with over 36,000 factories) to export premium products at the most advantageous prices in the industry. Our product lines cover light handicrafts, mechanical and electronic products, textiles, apparel, etc. In addition, we provide OEM and ODM services to meet our customers’ needs. We have sold thousands of products in different categories to buyers and wholesalers in 169 countries and regions worldwide.

Customer Feedback and Reputation

Customers often commend China-Base NingboForeign Trade Group Co., Ltd. for their innovative approach and dependable products. Their ability to meet diverse industry needs has earned them a loyal customer base. I have observed positive feedback regarding their after-sales support and timely deliveries.

Manufacturer 3: Samtec

Overview of Products and Services

Samtec focuses on high-speed connectivity solutions, including carbon steel connectors. Their offerings include heat-treated, drop-forged products that adhere to European and U.S. standards. I appreciate their emphasis on providing various sizes and custom designs to meet specific project demands. Their surface finishes, such as hot-dipped galvanized and electro-galvanized options, ensure long-lasting performance.

Strengths and Unique Features

Samtec’s strength lies in their specialization in high-speed connectivity. Their connectors are engineered for precision and reliability, making them ideal for industries requiring advanced solutions. I admire their dedication to innovation and their ability to adapt to evolving market needs.

Pricing and Market Position

Samtec positions itself as a leader in the high-speed connectivity segment. Their pricing reflects the premium quality of their products. I believe their focus on delivering exceptional performance justifies their market position and pricing strategy.

Customer Feedback and Reputation

Clients often highlight Samtec’s expertise and commitment to quality. Their reputation for delivering cutting-edge solutions has earned them recognition in the industry. I have seen positive reviews emphasizing their technical support and customer-centric approach.

Manufacturer 4: Phoenix Contact

Overview of Products and Services

Phoenix Contact provides a diverse range of carbon steel connectors tailored for industrial and commercial applications. Their products include heat-treated, drop-forged connectors that meet European and U.S. standards. I have observed their commitment to offering various sizes and custom designs, ensuring compatibility with unique project requirements. Their surface finishes, such as hot-dipped galvanized and electro-galvanized options, enhance durability and protect against corrosion. These features make their connectors suitable for demanding environments.

Strengths and Unique Features

Phoenix Contact excels in delivering reliable and high-quality solutions. Their connectors undergo rigorous testing to ensure compliance with industry standards. I value their focus on innovation, which allows them to integrate advanced technologies into their products. Their ability to provide tailored solutions for specific industries sets them apart. Additionally, their emphasis on corrosion-resistant finishes ensures long-lasting performance, even in harsh conditions.

Pricing and Market Position

Phoenix Contact positions itself as a mid-to-premium range manufacturer. Their pricing reflects the quality and durability of their products. I find their offerings cost-effective for businesses seeking reliable and long-term solutions. Their competitive market position highlights their ability to balance affordability with superior performance.

Customer Feedback and Reputation

Customers often praise Phoenix Contact for their consistent product quality and excellent customer service. Many reviews highlight their quick response times and professional support. Their reputation as a trusted manufacturer stems from their ability to meet diverse industry needs while maintaining high standards.

Manufacturer 5: Luxshare

Overview of Products and Services

Luxshare specializes in carbon steel connectors designed for performance and durability. Their product line includes heat-treated, drop-forged connectors that adhere to European and U.S. standards. I have noticed their focus on offering various sizes and custom designs to cater to specific project demands. Their surface finishes, such as self-colored and color-painted options, provide both functionality and aesthetic appeal.

Strengths and Unique Features

Luxshare stands out for its dedication to quality and adaptability. Their connectors are engineered to withstand challenging environments, making them ideal for heavy industry and marine applications. I appreciate their ability to deliver innovative solutions while maintaining compliance with international standards. Their emphasis on customization ensures that their products meet the unique needs of their clients.

Pricing and Market Position

Luxshare offers competitive pricing without compromising on quality. Their market position reflects their growing recognition as a reliable manufacturer. I believe their focus on delivering value makes them an attractive option for businesses seeking durable and cost-effective solutions.

Customer Feedback and Reputation

Clients frequently commend Luxshare for their dependable products and responsive customer service. Positive feedback often highlights their ability to deliver on time and provide tailored solutions. Their expanding presence in the global market reinforces their reputation as a trusted manufacturer.

Manufacturer 6: Honeywell International, Inc.

Overview of Products and Services

Honeywell International, Inc. offers a comprehensive range of carbon steel connectors for various industrial applications. Their products include heat-treated, drop-forged connectors that comply with European and U.S. standards. I have seen their dedication to providing various sizes and custom designs, ensuring compatibility with diverse project requirements. Their surface finishes, such as hot-dipped galvanized and electro-galvanized options, enhance durability and resistance to corrosion.

Strengths and Unique Features

Honeywell’s strength lies in its ability to cater to a wide range of industries. Their connectors are designed for high performance, making them suitable for critical applications. I admire their focus on innovation and their commitment to maintaining high standards. Their emphasis on quality control ensures consistent product reliability.

Pricing and Market Position

Honeywell positions itself as a premium manufacturer. Their pricing reflects the superior quality and performance of their products. I find their offerings to be a worthwhile investment for businesses requiring dependable solutions. Their strong market presence underscores their reputation as a leader in the industry.

Customer Feedback and Reputation

Customers often highlight Honeywell’s expertise and commitment to quality. Their reputation for delivering reliable products has earned them recognition across various industries. I have observed positive reviews emphasizing their technical support and customer-centric approach.

Manufacturer 7: FNW

Overview of Products and Services

FNW delivers a versatile range of carbon steel connectors tailored for plumbing and HVAC systems. I have observed their focus on heat-treated, drop-forged products that meet European and U.S. standards. Their offerings include various sizes and custom designs, ensuring compatibility with diverse project requirements. FNW provides surface finishes such as hot-dipped galvanized and electro-galvanized options, which enhance durability and protect against corrosion. These features make their connectors suitable for both residential and industrial applications.

Strengths and Unique Features

FNW stands out for its adaptability and commitment to quality. Their connectors are designed to perform reliably in demanding environments. I value their emphasis on flexibility, as they cater to specific customer needs with tailored solutions. Their use of advanced manufacturing processes ensures consistent product quality. Additionally, their corrosion-resistant finishes extend the lifespan of their connectors, making them a dependable choice for long-term projects.

Pricing and Market Position

FNW positions itself as a cost-effective manufacturer. Their pricing strategy reflects their dedication to delivering value without compromising on quality. I find their products to be an excellent option for businesses seeking reliable solutions at competitive prices. Their strong presence in the plumbing and HVAC sectors highlights their ability to meet industry-specific demands.

Customer Feedback and Reputation

Clients often praise FNW for their dependable products and responsive customer service. Positive reviews frequently highlight their ability to deliver on time and provide tailored solutions. Their reputation as a reliable manufacturer stems from their consistent focus on quality and customer satisfaction.

Manufacturer 8: Excel Metal

Overview of Products and Services

Excel Metal specializes in carbon steel pipe and tube fittings, including connectors. Their product line features heat-treated, drop-forged connectors that comply with European and U.S. standards. I have noticed their dedication to offering various sizes and custom designs, ensuring compatibility with unique project requirements. Their surface finishes, such as hot-dipped galvanized and color-painted options, enhance both functionality and aesthetic appeal.

Strengths and Unique Features

Excel Metal excels in providing comprehensive solutions for industrial applications. Their connectors are engineered for durability and strength, making them suitable for heavy-duty use. I appreciate their focus on innovation, as they integrate advanced technologies into their manufacturing processes. Their ability to offer customized solutions ensures that their products meet the specific needs of their clients. Additionally, their corrosion-resistant finishes protect the connectors in harsh environments.

Pricing and Market Position

Excel Metal offers competitive pricing while maintaining high standards of quality. Their market position reflects their growing recognition as a reliable manufacturer. I believe their focus on delivering value makes them an attractive option for businesses seeking durable and cost-effective solutions.

Customer Feedback and Reputation

Clients frequently commend Excel Metal for their dependable products and excellent customer service. Positive feedback often highlights their ability to deliver on time and provide tailored solutions. Their expanding presence in the global market reinforces their reputation as a trusted manufacturer.

Manufacturer 9: Tenaris

Overview of Products and Services

Tenaris focuses on carbon steel products for the energy industry, including connectors. Their offerings include heat-treated, drop-forged connectors that meet European and U.S. standards. I have observed their commitment to providing various sizes and custom designs, ensuring compatibility with critical infrastructure projects. Their surface finishes, such as hot-dipped galvanized and electro-galvanized options, enhance durability and resistance to corrosion.

Strengths and Unique Features

Tenaris stands out for its expertise in the energy sector. Their connectors are designed to withstand high pressure and temperature, making them ideal for pipelines and power plants. I admire their dedication to innovation and their ability to adapt to evolving industry needs. Their emphasis on quality control ensures consistent product reliability. Additionally, their corrosion-resistant finishes extend the lifespan of their connectors, even in extreme conditions.

Pricing and Market Position

Tenaris positions itself as a premium manufacturer. Their pricing reflects the superior quality and performance of their products. I find their offerings to be a worthwhile investment for businesses requiring dependable solutions. Their strong market presence underscores their reputation as a leader in the energy industry.

Customer Feedback and Reputation

Customers often highlight Tenaris’s expertise and commitment to quality. Their reputation for delivering reliable products has earned them recognition across various industries. I have observed positive reviews emphasizing their technical support and customer-centric approach.

Manufacturer 10: 4*4 Off Road

Overview of Products and Services

4*4 Off Road offers a specialized range of carbon steel connectors designed for heavy-duty applications. I have observed their focus on producing heat-treated, drop-forged connectors that meet both European and U.S. standards. Their product line includes various sizes and also accommodates custom designs to suit specific project requirements. They provide multiple surface finish options, such as hot-dipped galvanized, electro-galvanized, self-colored, and color-painted finishes. These finishes enhance durability and protect against corrosion, making their connectors suitable for demanding environments like mining, marine, and heavy industry.

Strengths and Unique Features

I find 4*4 Off Road’s commitment to quality and innovation impressive. Their connectors demonstrate exceptional strength and reliability due to the heat-treated and drop-forged manufacturing process. This ensures their products perform well under extreme conditions. They also excel in offering tailored solutions, which allows businesses to meet unique operational needs. Their extensive exporting experience, spanning over 15 years, highlights their ability to serve global markets effectively. Additionally, their ISO-certified management system and internal quality control team ensure consistent product excellence. I value their dedication to providing competitive factory pricing while maintaining high standards.

Pricing and Market Position

4*4 Off Road positions itself as a cost-effective manufacturer. Their pricing strategy reflects their focus on delivering value without compromising quality. I appreciate their flexible payment terms, which include a 30% deposit upfront and the balance payable against a copy of the bill of lading. This approach supports businesses in managing their budgets efficiently. Their competitive pricing, combined with their high-quality offerings, makes them an attractive choice for industries requiring durable and reliable connectors.

Customer Feedback and Reputation

Clients often commend 4*4 Off Road for their dependable products and excellent customer service. Positive reviews frequently highlight their quick shipment times and responsive after-sales support. Many customers also praise their ability to deliver customized solutions that meet specific project demands. Their long-standing presence in the market and strong reputation for reliability make them a trusted partner for businesses across various industries.

Comparison Table of Top 10 Manufacturers

Key Metrics for Comparison

Product Quality

I always evaluate product quality as the most critical factor. Manufacturers like Amphenol, TE Connectivity, and Samtec consistently deliver heat-treated, drop-forged carbon steel connectors. These products meet European and U.S. standards, ensuring durability and reliability. I also notice their attention to surface finishes, such as hot-dipped galvanized and electro-galvanized options, which protect against corrosion. Manufacturers like 4*4 Off Road and Phoenix Contact excel in offering self-colored and color-painted finishes, adding both functionality and aesthetic appeal. Their commitment to quality ensures long-lasting performance in demanding environments.

Pricing

Pricing plays a significant role in decision-making. I find manufacturers like FNW and Excel Metal offer competitive pricing without compromising quality. Their cost-effective solutions cater to businesses with budget constraints. On the other hand, premium manufacturers like Honeywell and Tenaris position themselves at the higher end of the pricing spectrum. Their products justify the cost through superior performance and reliability. I appreciate 4*4 Off Road’s flexible payment terms, which include a 30% deposit and balance payment upon delivery. This approach supports businesses in managing their finances effectively.

Reputation

Reputation reflects a manufacturer’s reliability and customer satisfaction. Amphenol and TE Connectivity have established themselves as industry leaders with decades of experience. Their consistent product quality and excellent customer service earn them high praise. I also value the growing recognition of Luxshare and 4*4 Off Road in global markets. Their ability to meet diverse industry needs highlights their professionalism. Positive customer reviews often emphasize timely deliveries, responsive support, and tailored solutions, which build trust and long-term relationships.

Unique Features

Unique features set manufacturers apart in a competitive market. I admire Samtec’s specialization in high-speed connectivity solutions, which cater to advanced industrial applications. Phoenix Contact and Luxshare stand out for their tailored solutions, offering various sizes and custom designs to meet specific project requirements. 4*4 Off Road impresses me with its ISO-certified management system and internal quality control team. These features ensure consistent product excellence. Additionally, their extensive exporting experience demonstrates their ability to serve international markets effectively.

Industry Applications

Carbon steel connectors serve a wide range of industries. I have seen their versatility in sectors like construction, heavy industry, and marine applications. Manufacturers like Tenaris focus on the energy sector, providing connectors that withstand high pressure and temperature. FNW specializes in plumbing and HVAC systems, offering solutions tailored to residential and industrial needs. 4*4 Off Road caters to demanding environments like mining, marine, and heavy industry. Their ability to provide industry-specific solutions ensures optimal performance and safety in critical applications.

After analyzing the TO 10 Carbon Steel Connector manufacturer list, I identified key strengths for each. Amphenol, TE Connectivity, and Samtec excel in delivering high-quality, innovative solutions. Their products meet rigorous standards and offer advanced features. For budget-conscious buyers, FNW and Excel Metal provide reliable and cost-effective options without sacrificing quality. I recommend evaluating your specific project needs, such as material standards, surface finishes, or custom designs, before making a decision. Choosing the right manufacturer ensures durability, safety, and long-term value for your applications.

FAQ

What is the significance of heat-treated, drop-forged connectors?

Heat-treated, drop-forged connectors provide enhanced strength and durability. I have seen how this process improves the structural integrity of carbon steel connectors, making them suitable for demanding applications. These connectors perform well under high stress and extreme conditions, ensuring reliability and safety.

What materials are commonly used for carbon steel connectors?

Manufacturers typically use carbon steel or alloy steel for these connectors. I prefer carbon steel for its balance of strength and affordability. Alloy steel offers additional properties like improved corrosion resistance and higher tensile strength, which are ideal for specific industrial applications.

What standards should I look for in carbon steel connectors?

I always recommend choosing connectors that meet European or U.S. standards. These standards ensure consistency, compatibility, and quality across various industries. Products adhering to these benchmarks often deliver reliable performance and meet safety requirements.

Are custom designs available for carbon steel connectors?

Yes, many manufacturers offer custom designs to meet specific project needs. I value this flexibility because it allows businesses to address unique operational requirements. Customization options include size variations, material selection, and surface finishes.

What surface finishes are available for carbon steel connectors?

Manufacturers provide several surface finish options, including hot-dipped galvanized, electro-galvanized, self-colored, and color-painted finishes. I find hot-dipped galvanized finishes ideal for corrosion resistance. Self-colored and color-painted finishes enhance aesthetic appeal while maintaining functionality.

How do I choose the right size for my application?

Selecting the correct size depends on your project requirements. I recommend consulting with the manufacturer or reviewing technical specifications to ensure compatibility. Manufacturers often provide various sizes or tailor products to meet specific needs.

What industries commonly use carbon steel connectors?

Carbon steel connectors serve industries like construction, heavy industry, marine, mining, and energy. I have observed their versatility in applications such as pipelines, bridges, pole line hardware, and rigging equipment. Their durability makes them suitable for both critical and everyday use.

How do manufacturers ensure product quality?

Reliable manufacturers implement ISO-certified management systems and internal quality control processes. I trust these measures because they ensure consistent product quality. Rigorous testing and adherence to international standards further guarantee reliability.

What payment terms do manufacturers typically offer?

Many manufacturers provide flexible payment terms. For example, I have seen terms like a 30% deposit upfront with the balance payable against a copy of the bill of lading. This approach helps businesses manage their budgets effectively.

Why should I consider corrosion-resistant finishes?

Corrosion-resistant finishes, such as hot-dipped galvanized or electro-galvanized options, protect connectors from environmental damage. I recommend these finishes for projects exposed to moisture, chemicals, or extreme weather. They extend the lifespan of the connectors and reduce maintenance costs.

Post time: Dec-05-2024